Following the pharma industry

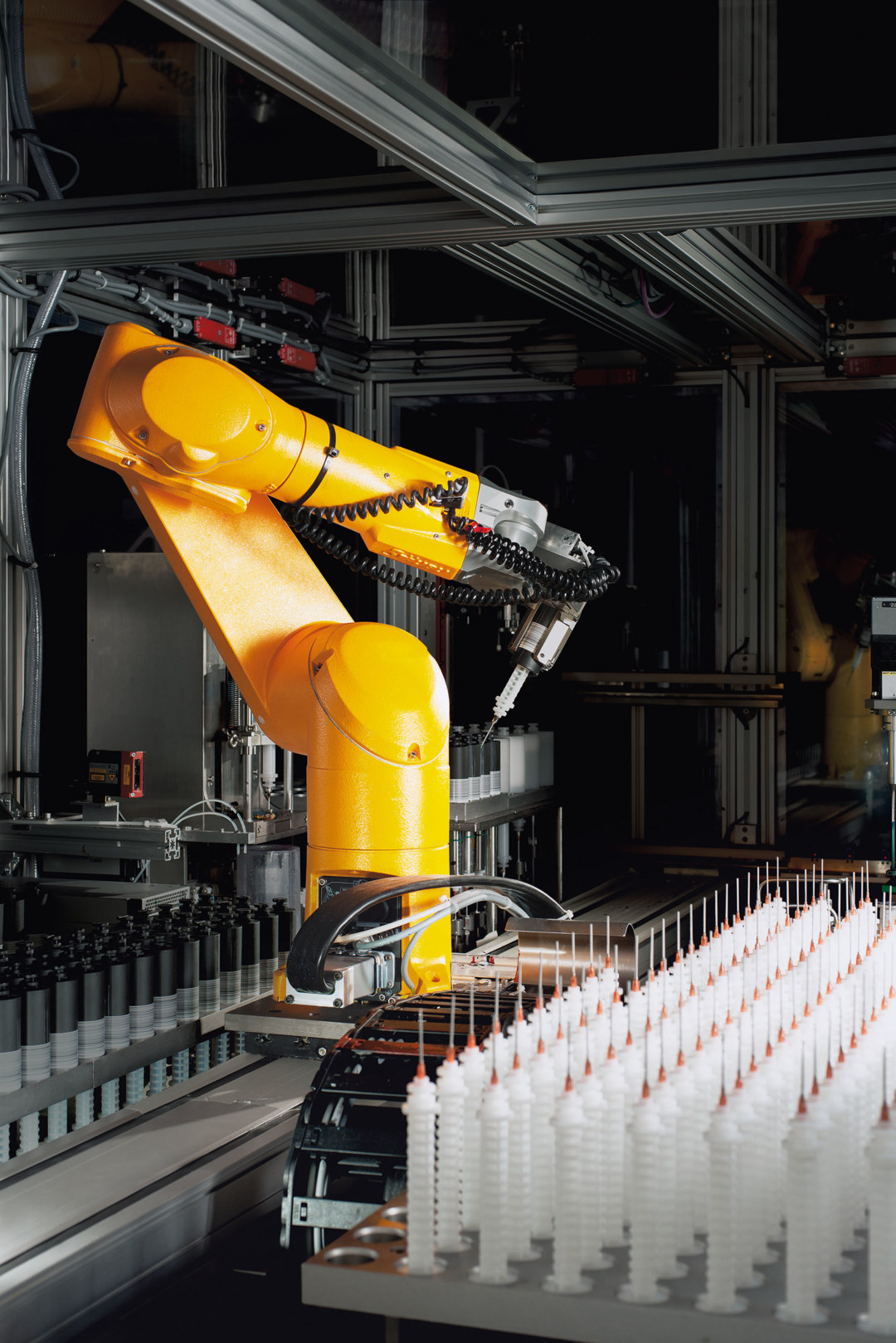

And so it continues, fully automatically, all night long. Although the robot appears to be repeating the same task over and over again, the reality is quite different. Each formulation sprayed onto the substrate varies slightly in this hunt for the perfect mix. But Sabine Ansorge and her colleagues know what to look for. The chemical engineer from the Color and Design Department at Wörwag manages the combinatorial laboratory and reprograms her robots daily, ensuring the gripper arm can work automatically through the night on the development of the liquid coatings. Wörwag opened the lab in 2006, but the robot still seems quite exotic. “It is a prototype,” says Sabine Ansorge.

The lab, hand-built by Bosch experts in collaboration with Wörwag, is an example of highthroughput technology. The inspiration came from the pharmaceutical industry. They started using automation to rapidly create a large number of different mixes, which helped to accelerate the development of new medicines. Today, high-throughput technology is also used in materials research and the development of paints and coatings. “The high-throughput technology gives us a competitive edge and allows us to specialize in certain areas,” says Ms. Ansorge.

Counting raw materials such as binders and pigments, the average coating consists of ten components. Finding the right formulation takes time, especially given the increasing requirements concerning adhesion, effect, color and viscosity.

Enormous time and material savings

Painting techniques are also becoming more complicated. The days when the base coat was first applied and dried, and then sprayed with a clear coat are long gone. Premium colors are now applied wet-in-wet onto the metal: two coats, one drying stage. In addition to that process, the Wörwag system can also simulate a process called IPP (Integrated Paint Process) where the primer is still wet when the colordefining base coat layer is applied. Says Sabine Ansorge, “It is important for us to be able to adapt the lab to the latest requirements.”

Of course, a reliable night worker needs a lot of support. Containers and syringes have to be cleaned every day, and more thorough cleaning is necessary on a weekly basis. The joints and movements of the robot arm are similar to the human arm, and it is able to work accurately to a tenth of a millimeter. Says Sabine Ansorge, “If any dirt accumulates in the system, our robot can get really capricious.”

But provided everything is clean, it will mix non-stop. In a 17-hour shift, the robot can create 70 samples with a two-layer coating, i. e. a total of 140 different formulations, which are specified by barcode. Afterwards, the results are evaluated, helping designers determine which mixes give the best quality results.

The time and material savings are enormous. A lab technician mixing by hand needs between 500 grams and one kilogram of liquid paint per mixture, and can produce about ten formulations per day. When you look at it like that, the combinatorial lab robot is the hands-down winner during the development phase. The robot arm high-throughput technology is a massive process accelerator.

Jill Rezes, Paint Laboratory Technician

Jill Rezes

completed her training as a paint laboratory technician at Wörwag three years ago and is part of the team of three in the robotic laboratory. “It takes a lot of technical knowledge about the plant to respond appropriately to unexpected events.”

Text: Reiner Schloz

Photos: Jojakim Cortis, Adrian Sonderegger