At the same time, the most important questions never change: “Where is the coating to be applied? What is it supposed to accomplish there?”, according to Bäuerle, who—along with his team—is about as close to a Wörwag motto that anyone can get: a deep understanding of surface finishing.

Bäuerle likes to cite the DIY store example: “If it were easy to paint a random surface, then anyone could buy paint off the shelf, spray it on, and that would be it.”

The coating systems requirements for industrial use today are as multilayered as a new car’s list of extras. The coating has to act as protection, look beautiful, and fulfill additional functions on a case-by-case basis. Three criteria that can vary in multiple ways. “Cars only have a few components anymore that are not coated in some form,” says Bäuerle.

That even applies to the engine. The old gray cast-iron block from which a colorful array of cables dangled has given way to visually pleasing aggregates with plastic covers sporting company logos. Even the back windows and headlight diffusers are being coated more and more often.

In general, the demands on the design become higher with each generation of cars. The manufacturers have long since even developed color philosophies for brake disks and brake calipers. The requirements demanded of the color systems are constantly changing because new materials are continually being put to use or known materials are assigned new tasks. The development of a shade has evolved into a total work of art that sometimes entails exploiting all method and product spectrum options. “We often have to develop three or four systems for one shade,” says Bäuerle.

“We check on the possibilities we already have to solve the problem. If we find that we need new techniques, then it gets really exciting.”

Wörwag’s innovative UV coating allows an electronic component made of aluminum and copper to be coated in a single work step.

A prospective customer asked Bäuerle about it during a trade fair and was amazed when he shot back with the reply: “Yes, we can.” The combination of materials was new to Wörwag as well. “Two metals, which can have an intense reaction if they create a galvanic cell under damp conditions, come together in this electronic component,” says Bäuerle.

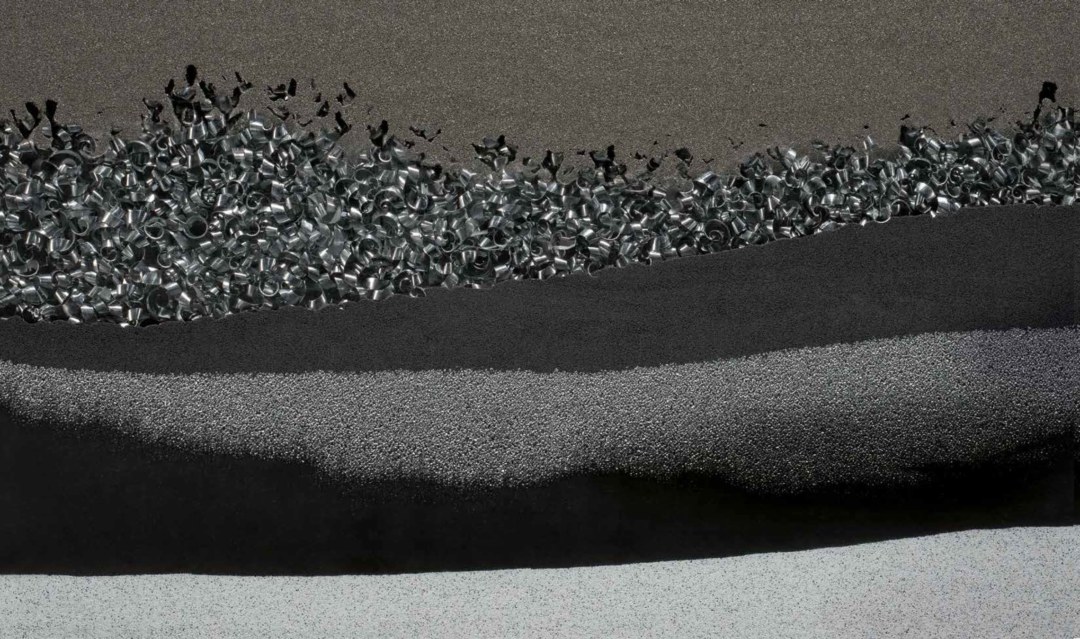

A prime example for the need to enable the innovative application of conventional materials using a coating solution. Even geometrically complex areas can be covered with the UV coating. The German construction machinery manufacturer Bomag, Wörwag, and the paint line producer Sturm joined forces to build a paint line that is able to coat and cure road roller drum casings in 16 minutes, thanks to the UV technology. A lamp with a diameter of 80 centimeters (31.5 in) and 400 watts output per square centimeter (0.155 sq in) was built in order to irradiate more inaccessible spots. There are many people behind success stories like this one.

Andy Bender from technical customer support at the Düsseldorf-based company Henkel can verify this: “It is essential that the coating manufacturer work together with the surface’s previous processor.”

The consumer goods giant’s laboratories are testing new methods of preparing the substrates for powder coating as closely as possible to actual conditions as well as the re-coatability of seam sealants.

That’s the reason the experts in Zuffenhausen like to draw on the Düsseldorf company’s expertise. Bender trains and advises Wörwag employees in the chemical treatment before the coating application. And so coating specialist, customer, and facility builder have grown together to form a highly effective team over the years. This “ground control” operation is especially challenged by the search for locking screws. Customers are also welcome to access this expertise. Wörwag offers seminars in Germany covering many coating and pretreatment topics several times a year.

Plastic surfaces are especially tricky. Although empirical data is available for the individual substrate groups, there is no way around testing the respective substrate type for specification fulfillment with the pertinent coating, as paint adhesion is influenced by numerous factors. The adhesion of the coating itself can be manipulated by means of binding agents or solvents, and by pigments as well as the type and amount of filler. However, the type of plastic used and the pretreatment also have a considerable influence on the adhesion. “While you simply clean sheet steel before coating it, the modern thermoplastic polyolefins require additional treatment for the coating to adhere well,” explains Silvie Mohr, Head of Materials Engineering at Wörwag. That primarily includes flame treatment and pretreating with plasma. The coating will then endure. “Stick-to-itiveness” is a virtue.

Text: Michael Thiem

Photos: Rafael Krötz, Frederik Laux