The powder coating clear coat W845 highgloss and W847 dull matt have been used in the bicycle industry for more than 15 years.

The water-based curing primer has been on the market since early 2015. The customer can choose between a water-based curing primer that can be combined with the paint systems of competitors on the market, or select a combination of powder-based primer with a liquid base coat and an acrylic powder clear top coat.

Another option is the two-coat combination of powder coating W898 primer and base coat in one product, finished with a colorless acrylic powder coating top coat. The system of primer, base coat, and clear coat protects the product like a shell.

“In low-temperature curing, our clear coat is the market leader,” emphasizes Bollinger.

While the industry standard for curing is 170 degrees Celsius (338 °F), the acrylic paints from Zuffenhausen can do with just 140 °C (284 °F; high gloss) and 150 °C (302 °F; matt).

That not only saves energy, but also gives the bicycle manufacturers greater flexibility in the early application of decorative decals. The excellent coverage of the surfaces and the smooth leveling both of the primer and the base coat enable easy and bubble-free application of undercoat decals.

Like the Dutch bicycle group Accell, the Hermann Hartje company of Hoya, Lower Saxony also relies on the Wörwag system, which gives customers a choice between three primers (black, white, gray) and two clear coatings. Beyond robustness and flexibility, the product is also impressive for its universal compatibility.

“Customers who use our primer can continue to use their previous base coat without any problem,” assures Bollinger.

The defenses are in place: the Wörwag coating system for bicycles defy mud and stones.

The system coating is primarily used on aluminum and chromoly alloys.

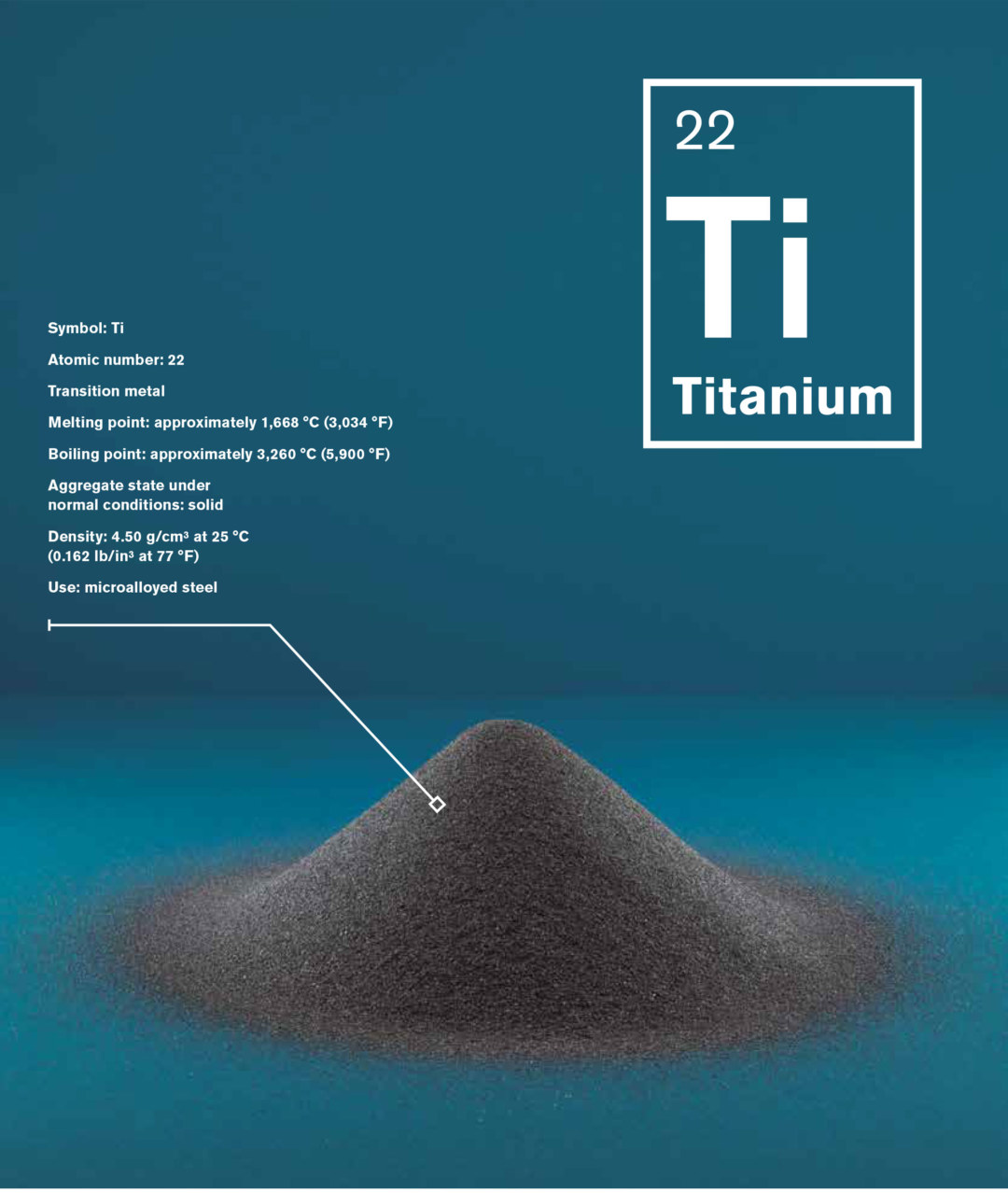

But it would also work with titanium, which some exclusive bicycle manufacturers use for their frames. Titanium forms a compact oxide layer on the surface that inhibits further corrosion. It is almost as strong as steel, but weighs 40 % less. Bollinger would certainly appreciate a bicycle frame made of this material on some of the steeper ascents …

Thorsten Bolliger

is convinced that the cycling boom is a lasting one. Speaking of raw titanium, which high-end bike manufacturers use primarily for hardtail (unsuspended) frames, three words spring to the market manager’s mind: “light, strong—and expensive.”

Photos: Frederik Laux; Lapierre