Driving force

Ramona Baumgärtel, today the head of the technology development department for pastes and top coats, was the driving force behind the development of the primer 15 years ago. Together with Georg Bussmann, who is now responsible for international technology and know-how transfer, she got the successful Wörwag product off the ground. The primer is used on components such as plastic bumpers and mirror shells on cars. “At present, with this composition and with these characteristics, there’s no one else who does it this way,” says Bussmann.

One for all

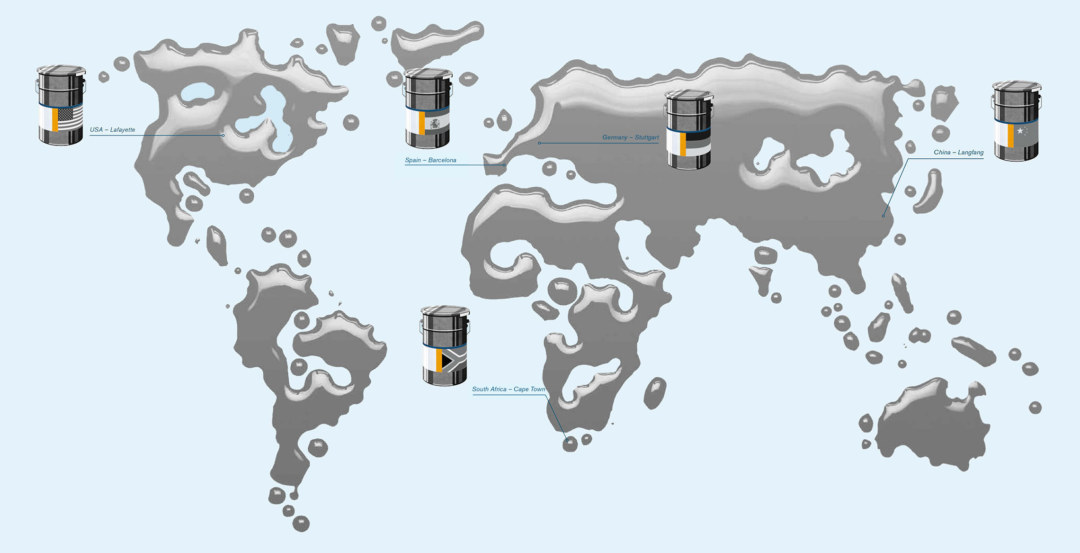

Allow me to introduce R1218. This is no code for some android from the future, but the indispensable Wörwag product of today. An evergreen that’s been impressing customers since its launch in 1999. Two thousand metric tons of it leave the plants in Zuffenhausen (Germany), Langfang (China), Lafayette (USA), Barcelona (Spain) and Cape Town (South Africa) every year—from five-kilo cans to containers weighing tons.

Many production locations, one recipe for success: R1218 is made to the same quality standards worldwide.

R1218 stands for the highest quality worldwide.

The primer’s advantages are legion: it can be used on almost any system, adheres to most materials, and fulfills the specifications of the carmakers. It can be delivered in countless colors and settings. With this single primer, the user covers all coating processes, whether dry, wet-in-wet or electrostatic.

R1218 also has another ace up its sleeve. It is permitted in the spare parts service of every carmaker. Parts are put into storage primed and can be reliably finished even after lengthy periods. “Many people don’t think of primers as sexy products because they don’t shine,” says Bussmann.

“You don’t even see them. For a reliable coating system, however, the primer is absolutely indispensable”, Georg Bussmann

Bussmann still clearly recalls the beginnings of the innovative primer system in the late ’90s. It took about three years to reach the launch phase.

During the process, the developers had to learn to dispense with the old standards. If you want to make a single product out of six or seven primer variants with different characteristics and applications, you have to find new ways of thinking. You have to be bold, try things out—and keep learning from experience.

The persistence paid off. The result was a primer unlike any that came before. R1218 is especially unique in the combination of binding agents. But ingredients alone do not make a good primer. “The trick is in the production process,” confides Bussmann.

Today R1218 is available in 130 recipes and color variants, from transparent to shiny, black to slate gray. Red, white, green, and beige are possible as well. For John Deere’s tractors, a very special green primer was developed. Another company wanted a glossy primer to make it easier to identify impurities during inspections. For vehicle door handles, Wörwag has a transparent variant that makes scratches less apparent.

Beyond its vast spectrum of uses, the primer also demonstrates the highest reliability. Bussmann: “Many customers demand a system that can be implemented with less technologically advanced procedures. And whatever they do with our primer, it works.” Particularly in markets like Brazil, Mexico, and China. In those countries, few factories are capable of combining the work steps in a coating system. That’s one reason why R1218 is the top-selling product group in China.

Thomas Stehle and Georg Bussmann (right) are two of Wörwag’s primer experts.

Wörwag offers custom solutions. That’s what Stehle’s coating tests are about as well. If the primer has to meet special requirements, the customer consultants are the first responders. They have the basic composition of R1218 and a modular system at their disposal.

This allows them to change parameters such as the viscosity of the application type. If the requirements are more complex, Stehle joins the fray. Reasons for altering the recipe might include substitution of raw materials to meet new environmental regulations or to avoid supply bottlenecks. And of course, that requires the entire testing program for the respective specification.

Extensive testing

New color tones and changes to the composition of the solvents require equally extensive testing. Depending on the intensity and complexity of the task, it can take up to six months for the modified primer to be ready. “Paint lives, and sometimes it behaves rather oddly,” chuckles Stehle. Some things are a lot different in the chemistry books. But if you think your way into things, you always get to the bottom of it.” That’s why it doesn’t bother him in his development lab when the paint goes missing from the test boards. Once in a blue moon.

Georg Bussmann,

today the head of International Technology Management (ITM), was involved in developing the primer 15 years ago. His motto: “Primers can be sexy too.”

Thomas Stehle

has worked for Wörwag since 1991. The trained commercial vehicle painter and paint and plastics technician is responsible for continuous primer development. His motto: “You can’t re-invent the wheel every day, but you have to keep it rolling.”

Text: Michael Thiem

Photos: iStock, Boris Schmalenberger