Depending on the customer’s wishes, the paint may be subjected to massive stress.

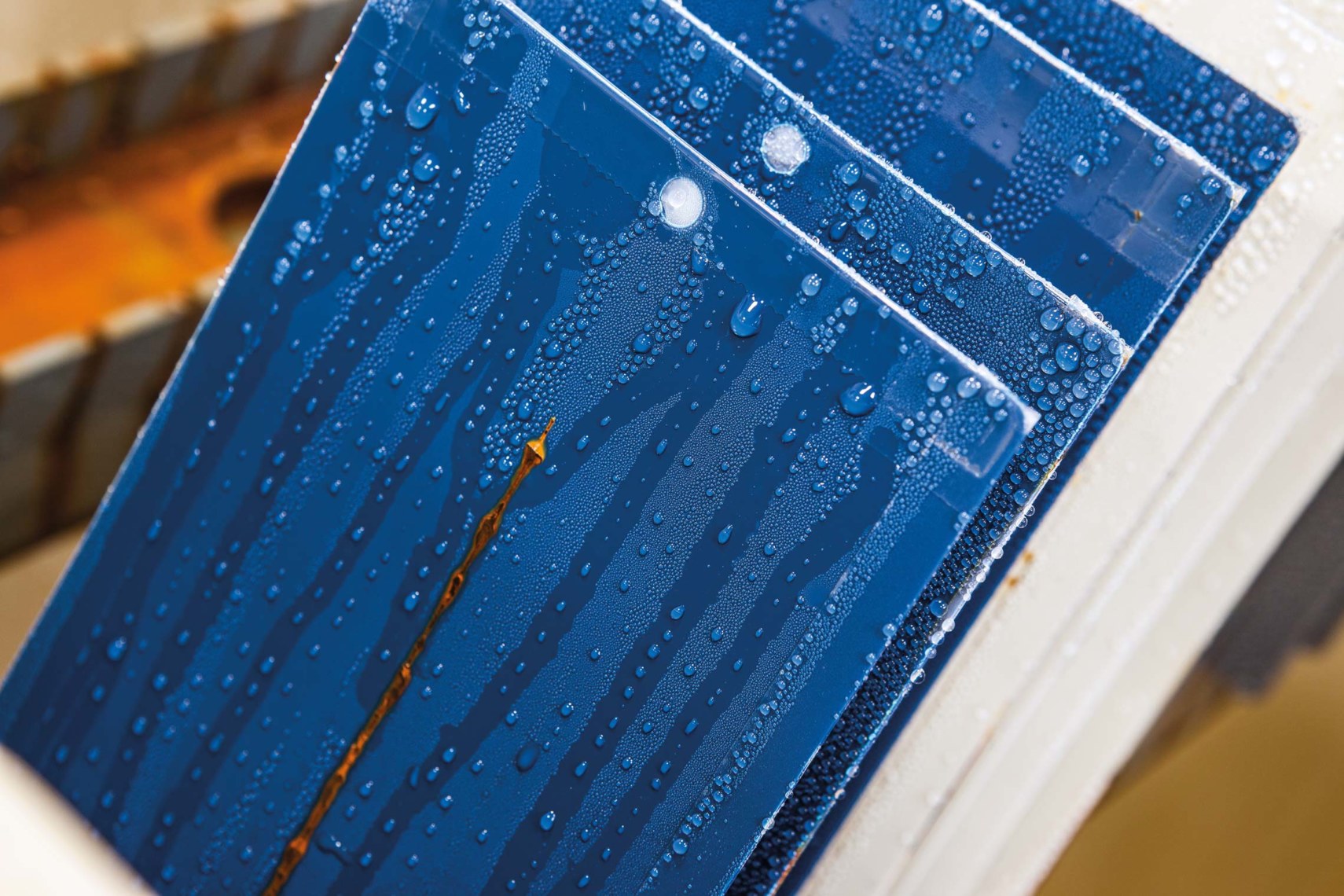

For instance, in the chemical resistance tests. In these tests, the painted component might be exposed to aggressive liquids such as brake fluid or sulfuric acid, or operating materials such as gasoline or diesel in the spotting method. In contrast, the physical-technological trials test the coating’s elasticity and adhesion.

Cross-hatching at defined millimeter intervals can give an indication of this. Less delicate is the stone chipping test, in which the substrate is pelted with chillediron grit (grain size: four to five millimeters) or washed gravel (grain size: 9 to 16 millimeters).

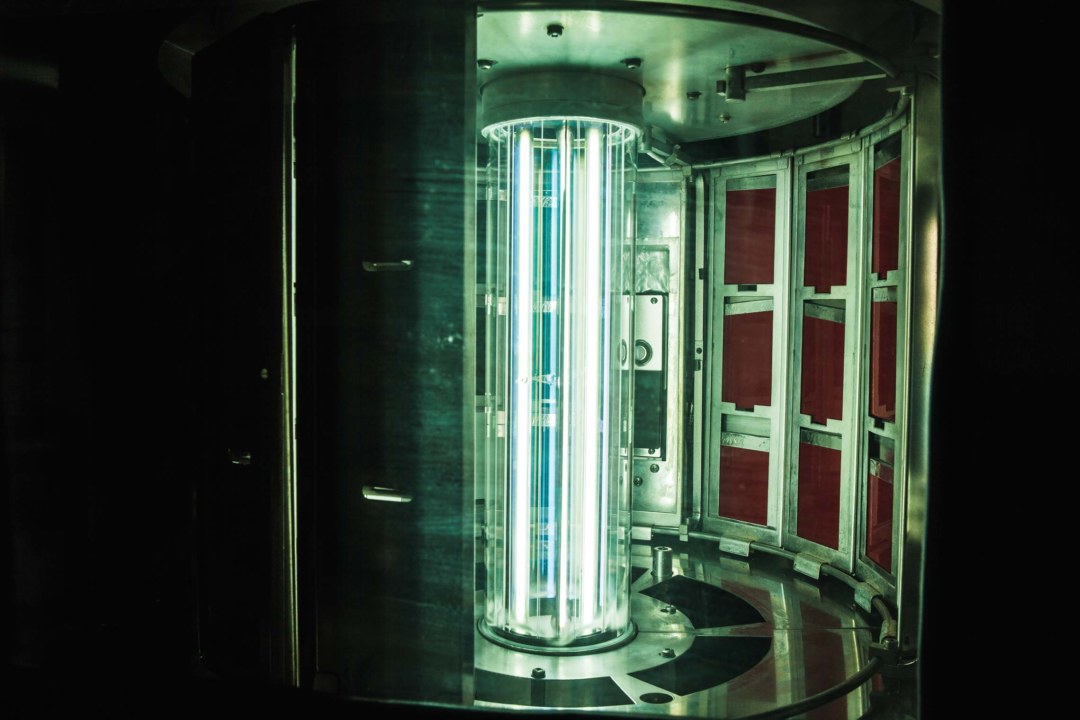

Two Months of Salt Spray

Even more extensive—and above all longer— are the corrosion tests in artificial environments. These are geared towards identifying rusting around the edges and potential weak points in the paint as well as surface rusting. The alternating climate test alone usually takes 10 to 15 weeks, in which the component is exposed to condensation, varying ambient temperatures, and salt spray. The test specimen spends up to 1,440 hours in an aerosol consisting of a five percent saline solution. DIN standards define how to evaluate any bubbles or cracks and the degree of corrosion upon conclusion of the tests is also well defined.

Heavy duty: Construction machinery has to stand the test of time. The paint does too—so it’s tested to the limit.

But Wörwag’s customer service goes even further. In many cases it’s not the paint that is responsible for any deficiencies that occur, but the way it was handled or the shape of the component.

“So then we take a closer look at the customer’s production facilities,” says Roth. Especially with powder coatings, users’ requirements go far beyond the mere test procedures. The powder-in-powder technique is viewed as especially economical, and is the top choice for manufacturers of agricultural and construction machinery, where components to be painted may weigh up to 30 metric tons and have plenty of edges and corners.

Jochen Reihs, head of the customer lab for vehicle manufacturing at Wörwag, notes: “The requirements in terms of adhesion, corrosion resistance, and efficiency of production are very high.” Working with customers, Wörwag has achieved considerable success over recent years. In the powder-in-powder technique, a single curing procedure is sufficient to bond the primer and the top coat to form a robust coating. Moreover, 85% of the exhaust heat can be fed back into the oven because—in contrast to wet paint—no solvents are used. To reduce energy consumption even further, work is under way on a low-temperature powder. In other words, at the same temperature but with a shorter curing time and higher throughput.

“The requirements in terms of adhesion, corrosion resistance, and efficiency of production are very high”, Jochen Reihs, head of the customer lab for vehicle manufacturing.

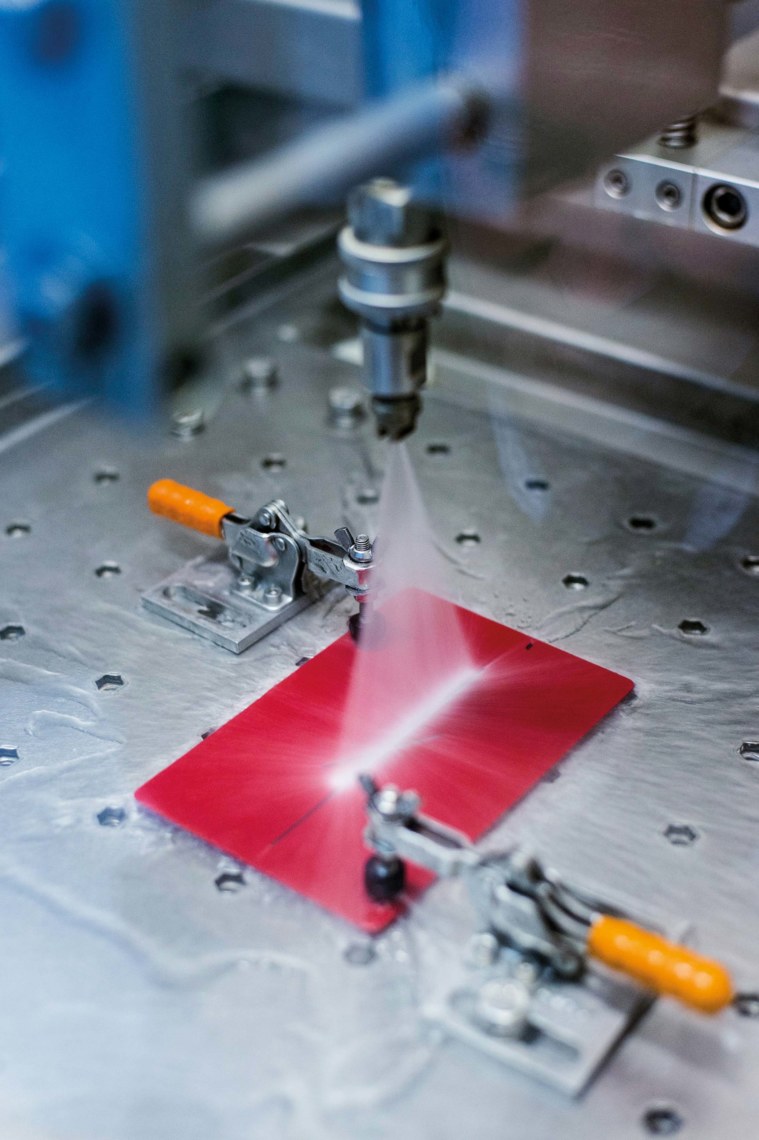

And development is continuing in the field of application technology too.

Tribo-charging promises optimal coating, adhesion, and efficiency. The powder is charged and the component is grounded. The powder is applied with a spray gun mounted on a special handle that makes it possible to easily reach every nook and cranny of the component.

Reihs: “This enables us to achieve the highest quality, greater efficiency, and a roughly 20 percent production increase for our external customers.” He adds that you have to look at the process both in its entirety as well as noting the details. And Wörwag regularly passes this knowledge on to customers in training courses. All course information is available at: www.woerwag.de under “Centre of Excellence.”

Gabriele Roth,

Director of the accredited test lab at Wörwag, is a member of the “General Test Methods” standards committee and thus knows all about paint testing procedures and their evaluation criteria. “In testing, we don’t just fulfill our customers’ requirements, but also advise them as to which tests are really useful for which purposes.”

Text: Reiner Schloz

Photos: Frederik Laux, Laurent Burst, Wörwag, Jos Schmid