“These thermosetting components have high thermal resistance and excellent crash properties as well as a lot of design potential,” says Wörwag laboratory director Wolfgang Fritz.

Work station with 400 horsepower: a good 50 % of the exterior of a driver’s cab consists of auxiliary components that require a special coating.

In order for 400-horsepower trucks weighing nearly 26 metric tons to be easily visible, a good paint job is more important than ever.

The transportation sector has long since placed a premium on visuals. Coating SMC components, however, requires a special type of paint. Why is that? Because when the components are made, it is not possible to completely prevent tiny air bubbles from forming inside them. “So we use a special base coat to prevent the air from outgassing and thereby damaging the paint during the baking process,” explains Fritz.

The W321 barrier primer reduces these outgases to a minimum. “This means there’s much less refinishing to do,” says Fritz. And that is an important consideration. After all, the diet these beefy vehicles are on should not drive costs up, but down.

Wolfgang Fritz

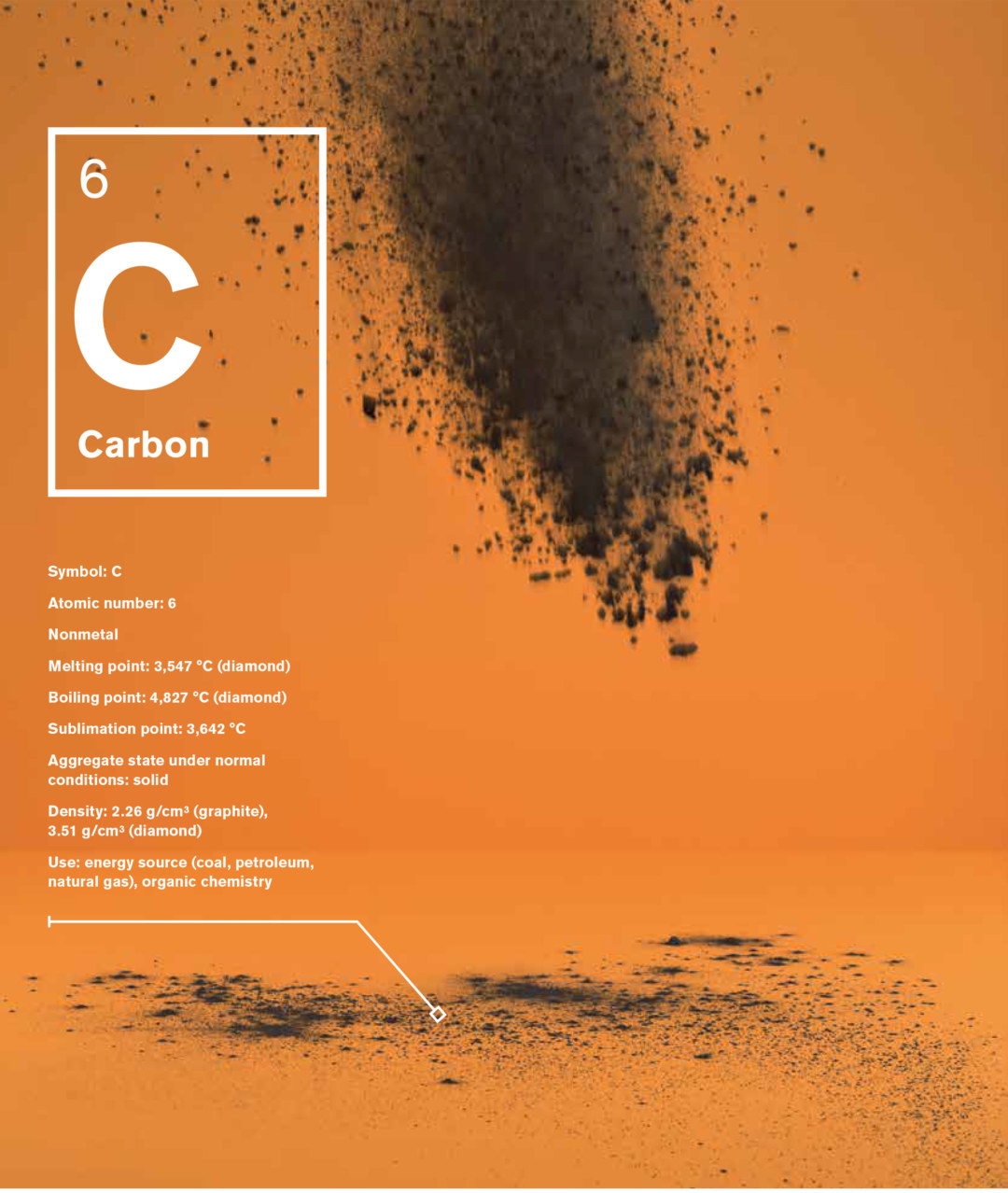

is a lab director in charge of special coatings for the plastic auxiliary components on commercial vehicles. “Thanks to our coating systems designed for SMC surfaces, we can now provide all the variants for commercial vehicles from a single source,” says Fritz—for whom the term “carbon” immediately triggers the association “diamond.”

Photos: Frederik Laux; Daimler AG