“It gives the most thorough shave and has the best battery life by far”, Stiftung Warentest consumer organization about the new „799cc-7 Wet&Dry“ (overall score 1,5)

Premium razors by Braun are equipped with sonic technology.

The motor operates at 10,000 micro-vibrations per minute and automatically adjusts to suit the beard thickness. In particularly difficult spots, Intensive mode is activated: the linear motor increases the sonic vibrations to such an extent that the razor manages even particularly hairy areas without loss of power.

Such technical superiority should be apparent to customers at a glance. That’s why the design, look, and feel of the different models plays a big part. The best possible shine, shock resistance, and resistance to sweat, salts, and bacteria are required.

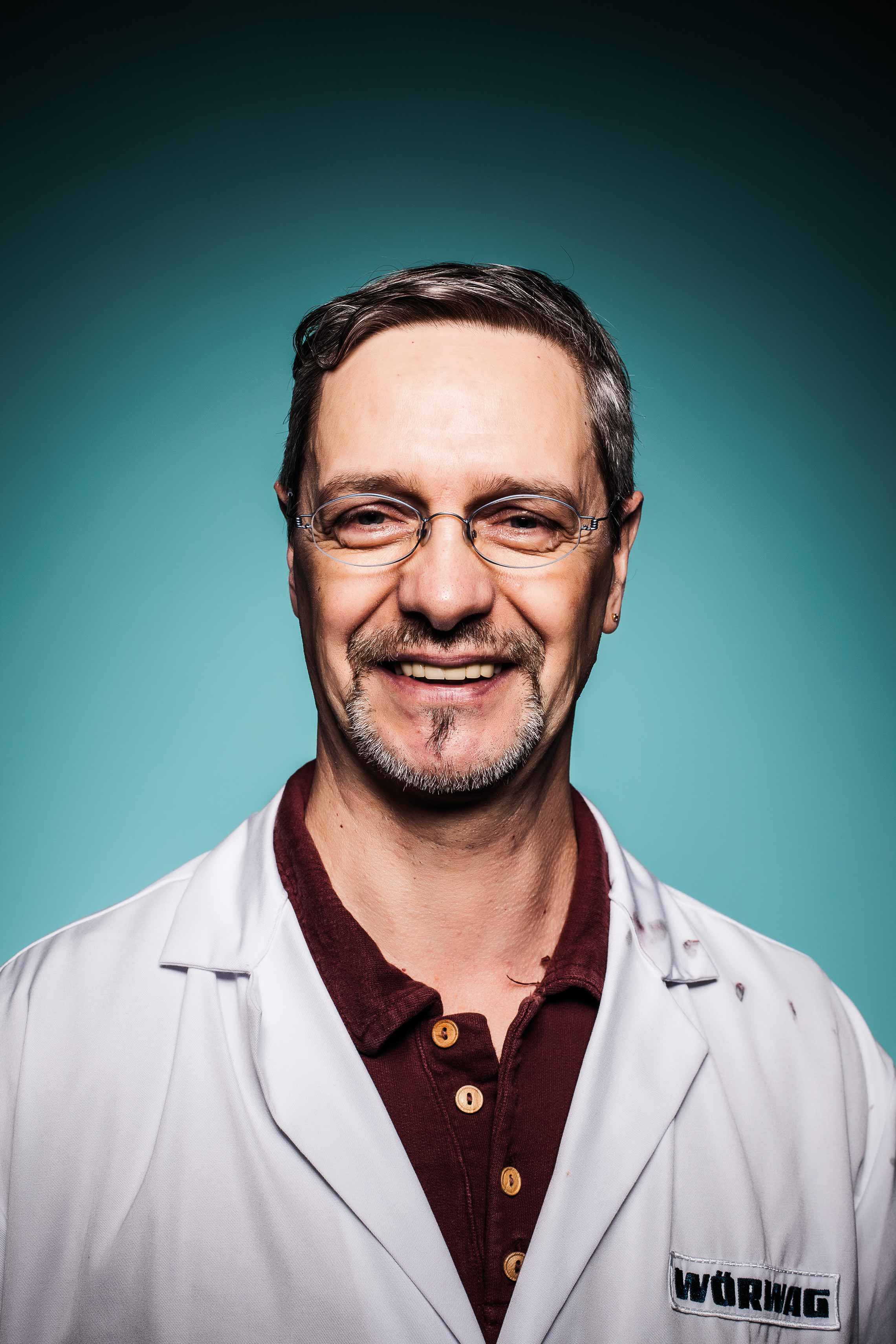

Resisting alcohol

However, the key lies elsewhere. Premium models are stored in a cleaning and charging station. At the touch of a button, this cleans the razor using a warm alcohol solution. “Alcohol is a strong solvent: it goes through virtually everything, even through coats of paint that are neither damaged nor weakened,” explains Andreas Bäuerle, head of the Industrial Liquid Paints department.

To solve this problem, the paint experts initially proceeded using the standard methods. Bäuerle: “That’s the nice thing about our work. We receive a special order and then we look to see what we already have, the wealth of experience we can refer to.” Braun clearly landed in the special preserve of vehicle paints. For Braun, even more than shine, it is the reliability and adhesion of the paint that counts, whether on steel, aluminum, or—as for the razor—on plastic. Project manager Peters: “The creative part of our work starts when we customize similar products to the customer’s desires.”

Hard testing program

Braun razors have three coats of paint to thank for their high-quality look and feel. A primer, the colored base coat, and a special clear coat ensure an attractive appearance as well as the best possible protection. The coating has been extensively tested. Following certification and approval by Wörwag, the Braun company tests the product again in their paint shop. After all, with industrial paint, laboratory and end results may differ.

It also makes sure that Wörwag always delivers the paint in the same quality, to a hair’s breadth. If nothing else, this requires a constant viscosity (ease of flow). Which is not so easy if you consider that the paint in each coat consists of 20 to 30 components.

As a result, the specialists in development and production at Braun and Wörwag have established a trusting collaboration over the years.

“We have an excellent working atmosphere. We get on very well as a team”, says Mathias Peters.

The partnership with Braun is not just an image factor, says Bäuerle.

There are also a large number of orders behind it. Premium razors are currently available in four colors: black, silver, metallic gray, and “noble metal.” In peak months, several tons of paint were delivered in each color. In turn, Braun values its partner’s service just as much as its product. As a result, the supplier from Zuffenhausen was awarded top marks. Which is as good a reason as any to contentedly run your fingers through your beard.

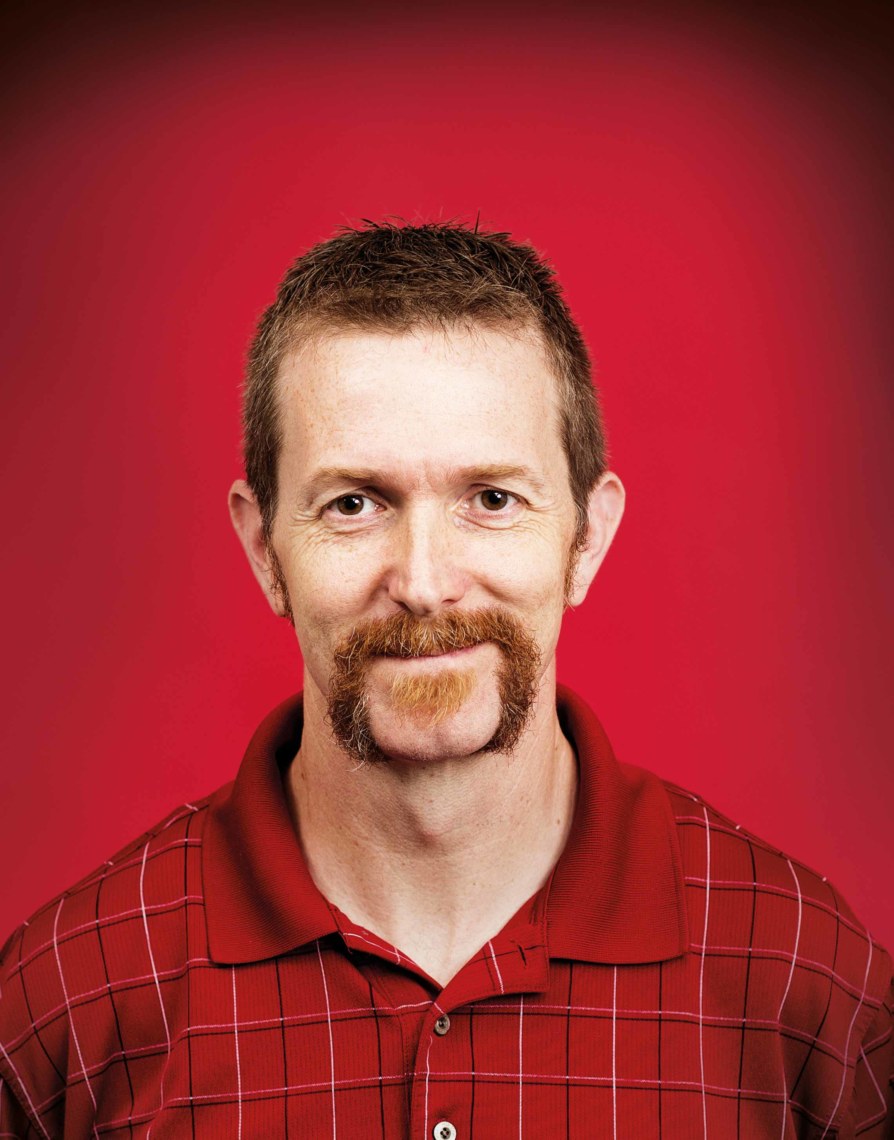

Mathias Peters

alues long and close partnerships with customers. The commercial technical assistant has been with Wörwag for 22 years, and has worked together with Braun for the last eight years. As a project manager in the industrial liquid coatings department, he’s especially proud of one thing: “We consistently deliver the exact same premium quality.”

Text: Reiner Schloz

Photos: Frederik Laux, Laurent Burst